TRIZ CONSULTING, INC.

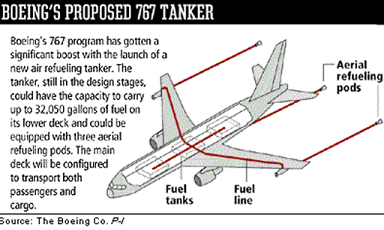

A team of Boeing engineers had been working hard for three years on a new 767 Tanker Transport development.

They experienced many difficult problems some of which were not resolved successfully.

John Higgs, former chief project engineer, offered some of difficult problems of the project for discussion as a part of

basic five-day TRIZ course offered in April 2000 in Wichita. According to John Higgs, the class had developed two ideal solutions.

"As a result of a TRIZ solution, the program was successfully launched with a customer who preferred the TRIZ solution over

the competitions solution for the same system, thereby ordering aircraft from Boeing."

TRIZ solutions developed during a TRIZ course helped Boeing to win 8 orders with $1.5B listing price.

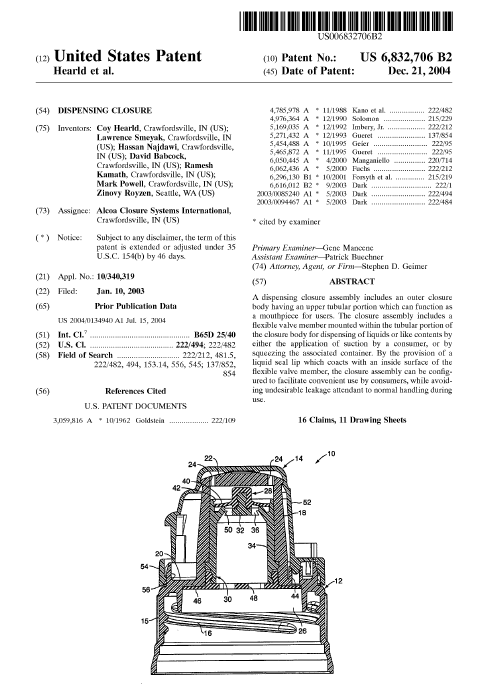

A team of Alcoa Closure Systems International, one of the biggest manufacturers of water bottle plastic caps, had been

working for a year on a new product development. They wanted to develop a cap for drivers and bicyclists which would

allow drinking water by using one hand only. A water bottle cap which avoid the need for manual positioning of the valve

and which permits dispensing water by application of suction, should open easily at suction pressures less than -0.38 psi.

The problem was that under normal use, sometimes internal container water pressure could be greater than 0.38 psi, and

thus the valve made as a flexible membrane can leak water. Also, water has to be released by squeezing the bottle with

pressure applied to the valve not less than, for example, 1 psi. The team tested a number of concepts but all tested

caps leaked before they asked us to help.

Using TOP-TRIZ, we formulate a contradiction: the membrane has to be flexible to be opened by sucking and the membrane

has to be stiff in order to prevent its undesired opening by water. Solution to this contradiction suggested by Physical

Contradiction Separation Rules lead to a new problem, also a contradiction. The team had developed a breakthrough concept

and several design implementations of the concept meeting all requirements by the end of the first day.

Larry Smeyak, Senior Technical Specialist wrote me the following.

"It is clear that through the application of TRIZ we were able to generate more concepts in two days than we were able

to accomplish in over a year." The best solution was protected by US Patent No. 6,832,706.

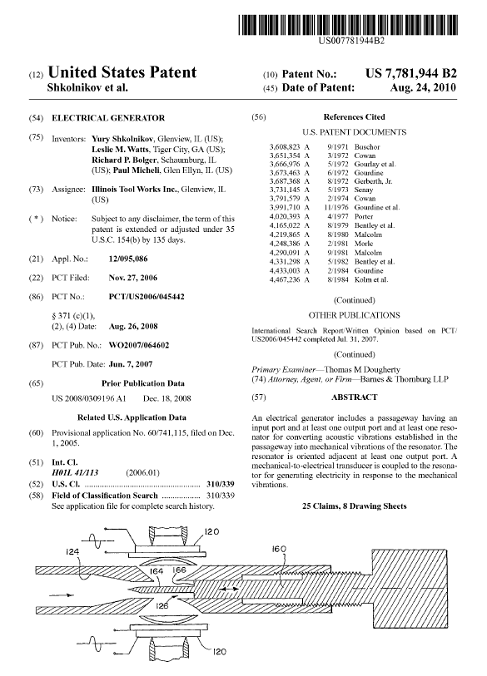

Illinois Tool Works (ITW) asked us to facilitate a team working on next generation of electrostatic spray gun.

The gun had three input components liquid paint supplied by a hose, airflow with its hose and high voltage cable.

High voltage cable represented both fire and safety hazard.

A competitor had introduced an electrostatic spray gun without high voltage cable. This gun had incorporated air turbine

connected with an electric generator. As a result, high voltage cable was eliminated.

Using TOP-TRIZ, the team developed several concepts for an electrostatic spraying gun with having neither high voltage

cable nor any moving parts. The company was granted with US Patents No. 7,781,944 and 8,134,066.

A client company had a warranty problem with a unit which failed too premature in service. For ten years the company had been changing the design of the unit, materials and the processes, however, the failure was not eliminated. Using TOP-TRIZ, the team revealed the actual mechanism of the failure overlooked for ten years and proposed a very simple and inexpensive solution to eliminate it with no additional parts. US Patent application is pending.

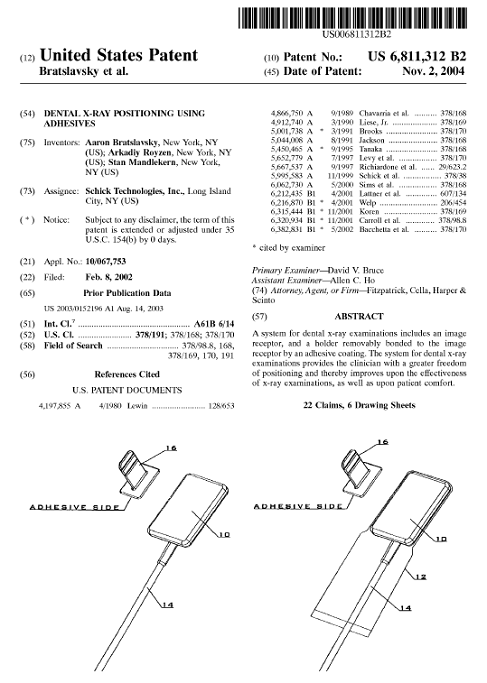

Shick Technologies, a manufacturer of x-ray dental sensors, had been working on continues improvements of its x-ray

dental sensor which very often resulted in the need to change a size of the sensor. The company produced also a set of

single use one-piece plastic holders to hold the sensor in the mouth of a patient in all needed positions. Any change

in any size of the sensor caused the need to for a new set of the holders and molds to manufacture them.

With our help in using TOP-TRIZ, all elements of the holders needed to hold the sensor were eliminated. We formulated a

new problem - how to hold the sensor. Solutions to the problem eliminated the need to change the holders and their

molds if any size of the sensor is changed. Moreover, the holders were simplified and their cost reduced.

US Patent No. 6,811,312.

A Client Company had developed a product with a new and very attractive feature, however, the US patent on the similar product was granted to a competitor. The Client Company had spent significant time without success trying to figure out a way to keep the product with its new feature while avoiding the competitor's patent infringement. Using TOP-TRIZ, the team formulated and solved problems for meeting the Client Company's objectives. Two-day session resulted in more than a dozen patentable solutions for alternative designs of the product having the desired feature.